Comprehensive Guide to OSHA H2S Training: Elevate Your Safety Standards

In today's industrial environment, safety is not just a priority—it's a fundamental aspect of operational excellence. Among the critical safety training programs, OSHA H2S training stands out as an indispensable requirement for industries dealing with hydrogen sulfide (H2S), a highly toxic and hazardous gas. This detailed guide aims to explore the importance of OSHA H2S training, its components, benefits, and how it can foster a safer workplace environment. At h2sonlinetraining.com, we are committed to providing comprehensive educational services that empower organizations to meet and exceed safety standards.

Understanding the Significance of OSHA H2S Training

The presence of hydrogen sulfide (H2S) naturally occurs in oil and gas fields, wastewater treatment plants, refineries, and other industrial sites. This gas is notorious for its pungent odor, resembling rotten eggs, but even at low concentrations, it poses significant health risks. Exposure to high levels of H2S can lead to devastating health effects, including respiratory paralysis, unconsciousness, or even death.

Recognizing these dangers, the Occupational Safety and Health Administration (OSHA) mandates strict safety protocols and training programs such as OSHA H2S training. This training equips employees and safety personnel with essential knowledge and skills to identify H2S hazards, respond appropriately, and minimize risks effectively.

The Core Components of OSHA H2S Training

1. Understanding Hydrogen Sulfide (H2S): Its Nature and Risks

This segment covers the chemical properties of H2S, sources of exposure, and potential health hazards. Participants learn to recognize the symptoms of H2S poisoning and understand its effects on the human body, emphasizing the importance of early detection and prevention.

2. Regulatory Standards and Compliance

To ensure safety compliance, workers are trained on OSHA standards, including 29 CFR 1910.1200 and other regulations specific to the industry. Understanding legal obligations helps organizations maintain compliance and avoid penalties.

3. Hazard Identification and Risk Assessment

Practical exercises teach participants how to identify potential H2S hazards in the workplace. This includes hazard recognition, proper use of detection equipment, and implementing risk assessment protocols to prioritize safety measures.

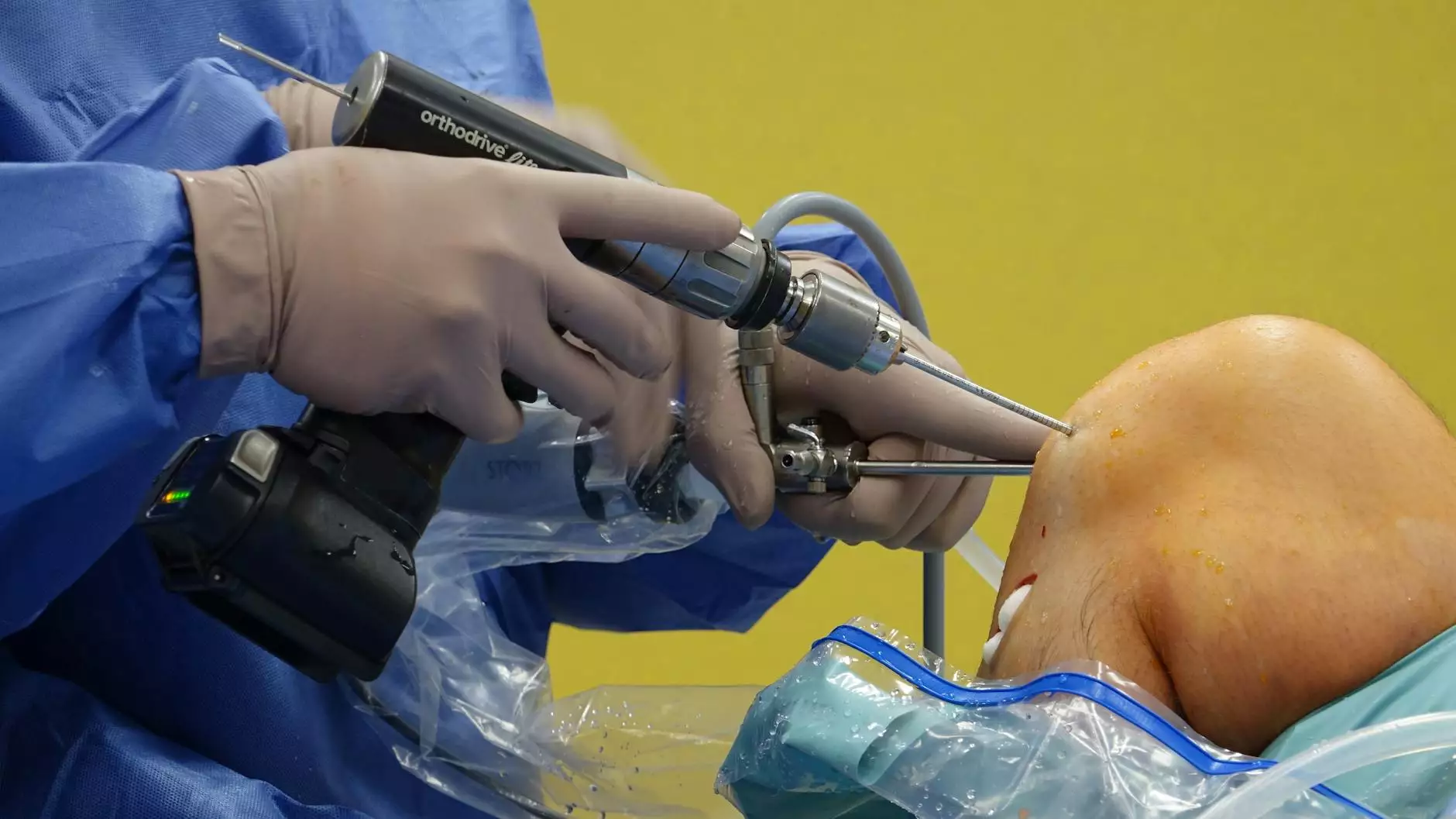

4. Use of Personal Protective Equipment (PPE)

Proper PPE is crucial when working in environments with H2S. Training emphasizes selecting the right protective gear, such as respirators and chemical-resistant clothing, and proper donning and doffing procedures to maximize safety.

5. Safety Procedures and Emergency Response

Participants learn step-by-step procedures for safe work practices, including leak detection, ventilation, and decontamination. Emergency response drills and evacuation plans are integral, ensuring readiness to respond swiftly to H2S incidents.

6. Communication and Alarm Systems

Effective communication protocols, including alarms, radios, and signaling systems, are vital for alerting personnel about H2S presence. Training ensures that workers understand how to interpret signals and respond accordingly.

Benefits of Implementing OSHA H2S Training in Your Business

- Enhanced Safety Culture: A well-trained workforce fosters a safety-first mindset, reducing workplace accidents and incidents related to H2S exposure.

- Legal and Regulatory Compliance: Regular training ensures your business complies with OSHA standards, avoiding costly fines and legal liabilities.

- Protection of Workforce: Proper training minimizes health risks, protecting employees from potentially fatal exposures and long-term health issues.

- Operational Continuity: Reducing accidents and health-related incidents leads to fewer work stoppages, maintaining productivity and profitability.

- Insurance Premium Benefits: Demonstrating compliance with safety standards can lead to lower insurance premiums and better business insurability.

Developing an Effective OSHA H2S Safety Program

Integrating comprehensive OSHA H2S training into your safety management system requires strategic planning. Here are key steps to develop an effective program:

- Conduct a Hazard Assessment: Identify areas and processes where H2S hazards may exist or occur.

- Engage Qualified Trainers: Work with certified professionals who can deliver up-to-date, industry-specific training modules.

- Create Customized Training Modules: Tailor training content to reflect your specific workplace conditions and hazards.

- Implement Hands-On Practical Exercises: Simulate real-life scenarios to reinforce knowledge and response skills.

- Maintain Training Records: Document all training activities to ensure compliance and facilitate audits.

- Regular refreshers and drills: Conduct periodic refresher courses and emergency drills to reinforce procedures and maintain preparedness.

The Role of Industry-Specific Training in Enhancing Safety

Different industries such as oil and gas, wastewater treatment, and chemical manufacturing have unique H2S hazards. Therefore, OSHA H2S training must be tailored to address sector-specific challenges:

- Oil and Gas Industry: Focuses on well-site safety, flare operations, and pipeline handling.

- Wastewater Treatment: Emphasizes leak detection, confined space entry, and ventilation strategies.

- Chemical Manufacturing: Covers handling of other toxic chemicals alongside H2S, and advanced detection methods.

Technological Advancements Supporting OSHA H2S Training

Modern technology enhances the effectiveness of safety training programs. These innovations include:

- Virtual Reality (VR) Simulations: Allow trainees to experience realistic emergency scenarios safely.

- Mobile Training Apps: Provide portable access to training modules, assessment tools, and safety resources.

- Advanced Detection Devices: Real-time sensors and alarms help identify H2S presence instantaneously, integrating seamlessly with training protocols.

- Online Learning Platforms: Offer flexible training schedules, facilitating continuous education for all employees.

The Importance of Continuous Education in H2S Safety

Safety training is not a one-time event but a continuous process. Regular updates and refreshers ensure personnel stay current with evolving industry standards, technological innovations, and regulatory changes. Businesses investing in ongoing education demonstrate their commitment to a culture of safety and operational excellence.

Why Choose h2sonlinetraining.com for Your OSHA H2S Training Needs?

At h2sonlinetraining.com, we specialize in delivering top-tier OSHA H2S training tailored to meet your industry-specific requirements. Our courses are designed by certified safety professionals and incorporate the latest industry standards. We offer:

- Flexible Online Courses: Learn at your own pace from anywhere.

- Comprehensive Course Content: Covering hazard recognition, emergency response, PPE, and compliance.

- Certification: Approved certificates that fulfill OSHA and industry standards.

- Ongoing Support: Access to updates, supplementary resources, and expert consultation.

Protect your workforce and uphold your safety commitments by choosing trustworthy, effective, and accredited OSHA H2S training. Our mission is to empower organizations with the knowledge and tools necessary to operate safely in hazardous environments.

Conclusion: Prioritizing Safety with Expert OSHA H2S Training

Effective OSHA H2S training is a vital pillar of any industrial safety management system. By understanding the dangers posed by hydrogen sulfide, adhering to regulatory standards, and implementing comprehensive training programs, businesses can significantly reduce risks and protect their most valuable asset—people.

Investing in high-quality training, such as the courses provided by h2sonlinetraining.com, ultimately results in safer work environments, enhanced corporate reputation, and compliance with OSHA mandates. Prioritize safety today for a more secure and productive future.